According to the Gas Safety (Instillation & Use) Regulations of 1998…

“It’s the duty of every employer or self-employed person to ensure that any gas appliance, installation pipe work or flue installed at any place of work under their control is maintained in a safe condition so as to prevent risk or injury to any person.”

As a business owner, you’d have known this – per logic if not per regulation. A reminder is never a bad thing though, right? And it’s good to know that the law takes our safety seriously. Keeping company employees and premises safe includes a couple of simple steps, check it out:

- Appliances should be serviced annually

- All services, installations and repairs should be carried out by a Gas Safe registered engineer

- Keep a record of any work that’s done

- Replace your CO alarms every five-to-seven years

- Consider a service plan if your business relies on heating or gas appliances.

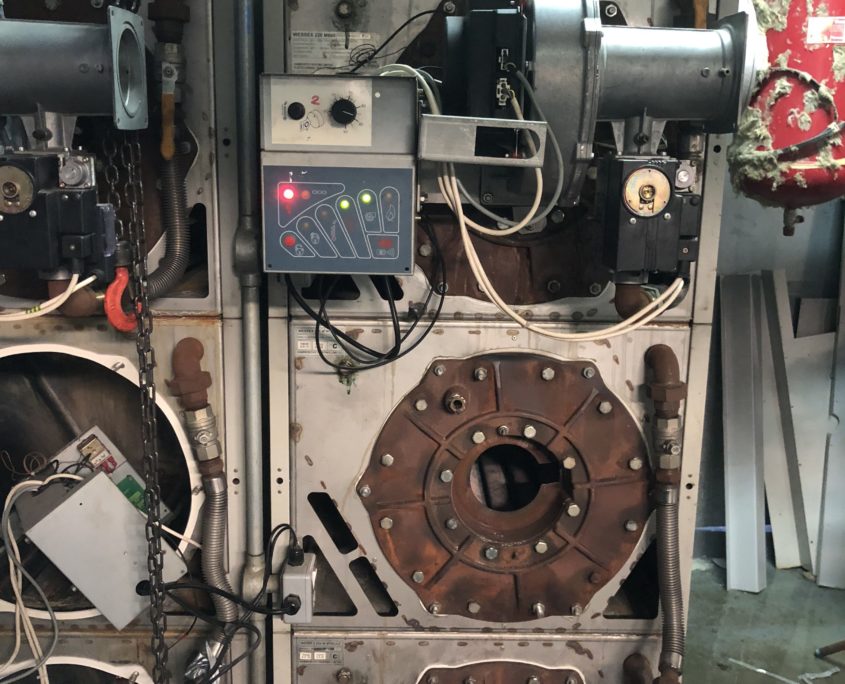

A business gas safety check is an inspection or service of your commercial gas appliance or boiler by a Gas Safe registered engineer, who will check your appliance or system to make sure its running safely and efficiently. This should be done on a yearly basis, and will also include:

- A safety inspection of your metre and all visible pipework

- A tightness test on your entire gas installation

- A boiler service

- A Gas Safety certificate once the inspection is complete.

For all your energy related questions or to book a business gas safety check, feel free to contact the CH Systems team on 0208 302 8149 or info@chsystems.cc.