Plant room installation and pipework – Royal Chelsea Hospital

Having carried out the enabling works for both the East and West Plant Rooms at the Royal Chelsea Hospital, the CH team moved on to carry out the installation of three Worcester GB162 boilers, supplied with frames and low loss headers to each plant room.

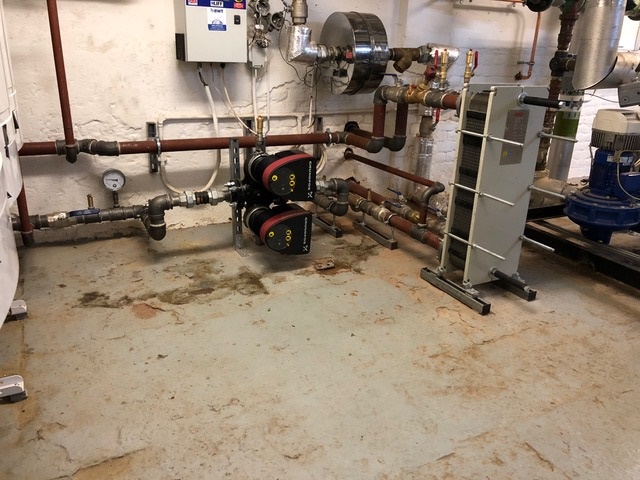

Due to the age of the existing system and a need to prolong the life of the new boilers, a decision was made to install a Plate Heat Exchanger, which offers hydraulic separation between the new and old system whilst allowing the necessary heat transfer to take place.

The team was also tasked with finding a suitable location for the associated Vessels and Pressurisation Units within some very compact/tight spaces. Looking at the images below, you’ll be able to see that usable space is at a premium; as such, a great deal of time was spent in consultation with the client over what would be the best and most acceptable use of the space we had.

This was by no means the largest project we have undertaken but the space constraints proved challenging – the team worked efficiently to get the job done and we are pleased with the end result.